We tried to vacuum the McPhonsen 247 over night, however there was a big leak from the bellow connector.

Ping thought the leak from the bellow, so he changed a new bellow. After than, he found the threads of two screws for mounting the bellow were badly damaged, which mainly caused the leakage.

After he put two new screws to tighten the bellow flange, vacuum of the pump system reached 3*10^-5 in 20 minutes.

Tuesday, September 26, 2006

Monday, September 25, 2006

Zeroth order spectrum form VUV spectrograph

We are using a 1-meter 86 degree grazing incidence model 247 McPherson spectrometer to measure the soft x-ray emission from laser plasma interaction. The detector is a single stage 2 inch diameter MCP with a potential of between of 200V to 1kV across it. The electron burst from the MCP is accelerated by another potential of 3 kV to 5 kV into a phosphor screen. The green photons from the phosphor is collected by a camera lens and sent to CCD camera. By adjusting the spectrograph, we obtained the 0-order spectrum.

We are using a 1-meter 86 degree grazing incidence model 247 McPherson spectrometer to measure the soft x-ray emission from laser plasma interaction. The detector is a single stage 2 inch diameter MCP with a potential of between of 200V to 1kV across it. The electron burst from the MCP is accelerated by another potential of 3 kV to 5 kV into a phosphor screen. The green photons from the phosphor is collected by a camera lens and sent to CCD camera. By adjusting the spectrograph, we obtained the 0-order spectrum.

Thursday, September 21, 2006

That's no laser, it's a particle accelerator

That's no laser, it's a particle accelerator

Geoff Brumfiel

Israeli physicists have turned a laser into a particle accelerator. Dubbed a paser — for particle acceleration by stimulated emission of radiation — the device accelerates bundles of electrons using the same principle as a laser.

At present it can only accelerate electrons by about 0.15% of their initial speed, but it could lead to compact particle accelerators and tabletop X-ray devices, according to Samer Banna of the Israel Institute of Technology in Haifa. He and his colleagues will publish their work in Physical Review Letters.

Conventional lasers exploit the quantum properties of atoms. An energy source is used to boost the electrons in a group of atoms into an elevated energy state. Passing light in the form of photons stimulates the atoms and causes the electrons to fall back to the lower energy level, emitting more photons in the process. These in turn stimulate more atoms and so on, so that a large number of photons are emitted. The photons are all identical, which makes the beam of light uniform.

Pasers work on a similar principle, but the output is accelerated electrons. Packets of electrons are fired into a cloud of excited carbon dioxide gas. As in a laser, the gas releases a large number of identical photons. But those photons are instantly absorbed by the passing electrons, which get an energetic kick, and leave the device moving more quickly than when they came in.

The fact that the paser uses atoms to speed up electrons sets it apart from other particle accelerators. "This is unlike anything that's come before," says Eric Colby of the Stanford Linear Accelerator Center in California. The unique mode of action makes the paser far more efficient than current machines, which achieve acceleration by generating enormous electric fields inside huge cavities. Colby is optimistic about the paser's potential. "It's a pretty small effect now," he says, "but there are strong technical reasons to believe that a very significant gain in acceleration is possible."

Levi Schächter, of the Israel Institute of Technology, believes that the paser could also make its mark as a source of X-rays. If the high-speed electrons have their paths bent after they leave the device, they will release a laser-like beam of X-rays that could be used for medical or nanotechnology applications. But Schächter is reluctant to guess exactly what may come of the technology. "In Hebrew we say, 'It's difficult to make predictions, particularly regarding the future'."

It wouldn't be possible to produce the exact equivalent of a laser beam with electrons — the Pauli exclusion principle states that electrons cannot exist in the same energy state at the same time. But laser equivalents can in theory be created for other types of particle, such as gravitons (which carry the gravitational force), phonons (packets of vibration) or some nuclei — if a system can be found that emits them. In June, for example, a group of researchers reported building a sound laser, or saser, that uses semiconductor technology to create a uniform beam of phonons (A. J. Kent et al. Phys. Rev. Lett. 96, 215504; 2006).

Colby says that these new systems show that it is easier than one might think to generate laser-like behaviour. "If you can store energy in a material," he says, "a great many things can be done."

Geoff Brumfiel

Israeli physicists have turned a laser into a particle accelerator. Dubbed a paser — for particle acceleration by stimulated emission of radiation — the device accelerates bundles of electrons using the same principle as a laser.

At present it can only accelerate electrons by about 0.15% of their initial speed, but it could lead to compact particle accelerators and tabletop X-ray devices, according to Samer Banna of the Israel Institute of Technology in Haifa. He and his colleagues will publish their work in Physical Review Letters.

Conventional lasers exploit the quantum properties of atoms. An energy source is used to boost the electrons in a group of atoms into an elevated energy state. Passing light in the form of photons stimulates the atoms and causes the electrons to fall back to the lower energy level, emitting more photons in the process. These in turn stimulate more atoms and so on, so that a large number of photons are emitted. The photons are all identical, which makes the beam of light uniform.

Pasers work on a similar principle, but the output is accelerated electrons. Packets of electrons are fired into a cloud of excited carbon dioxide gas. As in a laser, the gas releases a large number of identical photons. But those photons are instantly absorbed by the passing electrons, which get an energetic kick, and leave the device moving more quickly than when they came in.

The fact that the paser uses atoms to speed up electrons sets it apart from other particle accelerators. "This is unlike anything that's come before," says Eric Colby of the Stanford Linear Accelerator Center in California. The unique mode of action makes the paser far more efficient than current machines, which achieve acceleration by generating enormous electric fields inside huge cavities. Colby is optimistic about the paser's potential. "It's a pretty small effect now," he says, "but there are strong technical reasons to believe that a very significant gain in acceleration is possible."

Levi Schächter, of the Israel Institute of Technology, believes that the paser could also make its mark as a source of X-rays. If the high-speed electrons have their paths bent after they leave the device, they will release a laser-like beam of X-rays that could be used for medical or nanotechnology applications. But Schächter is reluctant to guess exactly what may come of the technology. "In Hebrew we say, 'It's difficult to make predictions, particularly regarding the future'."

It wouldn't be possible to produce the exact equivalent of a laser beam with electrons — the Pauli exclusion principle states that electrons cannot exist in the same energy state at the same time. But laser equivalents can in theory be created for other types of particle, such as gravitons (which carry the gravitational force), phonons (packets of vibration) or some nuclei — if a system can be found that emits them. In June, for example, a group of researchers reported building a sound laser, or saser, that uses semiconductor technology to create a uniform beam of phonons (A. J. Kent et al. Phys. Rev. Lett. 96, 215504; 2006).

Colby says that these new systems show that it is easier than one might think to generate laser-like behaviour. "If you can store energy in a material," he says, "a great many things can be done."

Wednesday, September 20, 2006

Grating Cleaning Procedure

David found the compressor grating became dirty, that caused the output energy lower. He suggested to order a new grating or clean the grating. We ordered a new grating from Spectra-Physics, the model number is 9800-2680, the size is 30x110x16. The grating cleaning procedure is listed below.

----------------------------------------

Direct Contact Method:

Spectra-Physics RGL provided the direct contact method and they have used it on gratings with

minor dirt or oil contamination.

1. Select a pan large enough to accommodate the grating as well as being able to allow unrestricted movement around the grating. A 20cm x 20cm x 5cm (8" x 8" x 2") aluminum baking pan was used here.

2. Heat water temperature to 32 C (90F) +/-1C.

3. Mix together Woolite 2 capfuls of (or equivalent) with water.

http://www.fabriclink.com/Woolite/Home.html in case one is not familiar with Woolite.

4. Place grating in the soapy water pan.

5. The water should cover the top surface of the grating by 10-12mm.

6. Adjust water level in pan accordingly and maintain water temperature of 32-34 C.

7. Grating is to be lightly stroked with a cotton ball in the direction that is parallel to the groove.

7.1. Note: "Stroking" means to drag the cotton ball across grating, applying no physical pressure, allowing just the weight of the wet cotton to contact the grating surface.

8. Remove the grating from the soapy water pan and rinse with distilled water. Make sure that the water is flowing down the grooves, not across the grooves.

9. Rinse the grating with isopropyl alcohol (rubbing alcohol 70% by volume) with the alcohol going down the grooves not across. Be careful for the alcohol will dissolve the ink on the grating. I would advise that one write the groove density on the grating with a pencil.

10. Blow dry the grating with nitrogen (or clean "air") starting at the top allowing the alcohol to run down the grooves. As with the rinsing, blow down the grooves not across them. When testing this method at SPMV, dry nitrogen at a pressure of 50 psi through a 6mm dia. nozzle was used. This dried the grating well.

Bake Out Method

The bake out method is generally used when the grating exhibits a film or 'fog' on the surface of the grating. The cause and/or composition of this film is unknown. However, baking out the grating usually results in the elimination of the film.

Place gratings in the oven with the gold surface up. Take care when placing the gratings so that the gold surface does not come in contact with anything.

Ramp up oven over at a 2 hour rate to 105 C.

Bake the gratings for 2 hours at 105 C.

Ramp down the oven at a 2 hour rate to room temperature.

----------------------------------------

Direct Contact Method:

Spectra-Physics RGL provided the direct contact method and they have used it on gratings with

minor dirt or oil contamination.

1. Select a pan large enough to accommodate the grating as well as being able to allow unrestricted movement around the grating. A 20cm x 20cm x 5cm (8" x 8" x 2") aluminum baking pan was used here.

2. Heat water temperature to 32 C (90F) +/-1C.

3. Mix together Woolite 2 capfuls of (or equivalent) with water.

http://www.fabriclink.com/Woolite/Home.html in case one is not familiar with Woolite.

4. Place grating in the soapy water pan.

5. The water should cover the top surface of the grating by 10-12mm.

6. Adjust water level in pan accordingly and maintain water temperature of 32-34 C.

7. Grating is to be lightly stroked with a cotton ball in the direction that is parallel to the groove.

7.1. Note: "Stroking" means to drag the cotton ball across grating, applying no physical pressure, allowing just the weight of the wet cotton to contact the grating surface.

8. Remove the grating from the soapy water pan and rinse with distilled water. Make sure that the water is flowing down the grooves, not across the grooves.

9. Rinse the grating with isopropyl alcohol (rubbing alcohol 70% by volume) with the alcohol going down the grooves not across. Be careful for the alcohol will dissolve the ink on the grating. I would advise that one write the groove density on the grating with a pencil.

10. Blow dry the grating with nitrogen (or clean "air") starting at the top allowing the alcohol to run down the grooves. As with the rinsing, blow down the grooves not across them. When testing this method at SPMV, dry nitrogen at a pressure of 50 psi through a 6mm dia. nozzle was used. This dried the grating well.

Bake Out Method

The bake out method is generally used when the grating exhibits a film or 'fog' on the surface of the grating. The cause and/or composition of this film is unknown. However, baking out the grating usually results in the elimination of the film.

Place gratings in the oven with the gold surface up. Take care when placing the gratings so that the gold surface does not come in contact with anything.

Ramp up oven over at a 2 hour rate to 105 C.

Bake the gratings for 2 hours at 105 C.

Ramp down the oven at a 2 hour rate to room temperature.

Hurricane Compressor alignment procedure

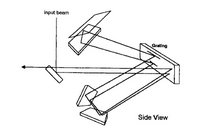

The compressor consists of one grating, one horizontal retromirror set, and one vertical retro-mirror.

The compressor consists of one grating, one horizontal retromirror set, and one vertical retro-mirror.(1). Adjust the grating position horizontally and rotate the grating so that the input beam on the right bottom. The first order diffracted beam out of the grating should be centered on the horizontal retro-mirror without clipping of the spectrum.

(2). Morve the horizontal retro-mirror so that the spatially dispersed spectrum on the grating left bottom. The spectrum on the grating should be the same height as the input beam.

(3). Move and rotate the vertical retro-mirror so that the beam is retrace back to left top of the grating. Make sure the vertical retro-mirror is positioned as close as possible to the input beam without clipping the input beam.

(4). The beam coming out the compressor should be centered to the output port of the Hurricane with beam height equals to 4".

(5). If the beam height is not centered to the output port, one can adjust the y-axis of the vertical retro-mirror to center it.

How to adjust the Hurricane regen

(1). Blcok the Mai-Tai seed beam.

(1). Blcok the Mai-Tai seed beam.(2). Disable the Pockel Cell trigger.

(3). Taken the half-wave plate from PC1 postion, put it behind PC2, then rotate this plate to maximumize the output power. (in our case, ~550mW@745nm in free running).

(4). Tune the Evolution green beam last steering mirror to peak the output power.

(5). The output power should not be decrease when centering the iris.

(6). Adjust the half-wave plate to reduce the power minimum.

(7). Mark half-wave plate, then move it back to PC1 postion.

(8). Adjust the seed beam steering mirrors to make the time gap between free runing pulse and seed pulse around 70 ns.

Monday, September 18, 2006

Replaced X-ray gun ion gauge

Because the old ion gauge for x-ray gun did not work stably, I ordered a new ion gauge from MDC. The old gause was replaced as soon as I got this new gauge. The vacuum reached around 3x10^-5 Torr before I left the lab.

For LLG-TWIN, I have to change the gases twice to make sure the timing trigger steadily. The laser energy would be decreased in a couple of minutes after first gas filling, then it's hard to synchronize the seed beam and the TWIN. After evacuating the chamber and refilling the gases, the TWIN became better.

For LLG-TWIN, I have to change the gases twice to make sure the timing trigger steadily. The laser energy would be decreased in a couple of minutes after first gas filling, then it's hard to synchronize the seed beam and the TWIN. After evacuating the chamber and refilling the gases, the TWIN became better.

Saturday, September 16, 2006

Timing delay for target nozzle

In this week, we tried to focus the laser beam to the Xe cluster for measuring the Xe(L) emission. Because the nozzle has been changed, the timing delay between laser pulse and nozzle trigger must be adjusted. On Monday this delay time was about 478 us, however it changed to 410 us next day, on Friday the dealy was 491us. The range is around 10 to 80 us, beyand these values, we saw nor Xe(M) light on the top CCD neither any singals from crystal spectrometer (for measuring L-shell light).

Wednesday, September 13, 2006

Trigger signals from frequency divider

Sometimes the signal from the frequency divider was strange. We used two frequncy divider, No.1 is 2 times divider, No. 2 is 10 times. The seed pulses with 4 Hz repitation rate was divided to 0.2 Hz by these frequncy dividers. I found the No.1 sent disordered signals. After moved this divider from one rank to the another, the problem was disappeared. So I used the same DC power supply to energize these dividers now.

The Relay K4 for cooling fans could not run well, previously it became well after only tightening the connectors. Yesterday I had to tighten many times, I replaced it this morning.

The Relay K4 for cooling fans could not run well, previously it became well after only tightening the connectors. Yesterday I had to tighten many times, I replaced it this morning.

Wednesday, September 06, 2006

Windows cleaning and O-rings changed

I removed the windows of both tubes. The windows of the long tube are a little bit dirty, maybe the energy dropping was caused by the leakage. The most possibility is the leak from the windows. Firstly it's diffcult to take the window from the holder, I dropped some ethonal into the gap between window and the holder, the window became loose and was easy to remove. I cleaned windows carefully. Unfortunately I found there was a light breakage inside the window, we should order new window for the long tube.

I installed all windows in the afternoon, and made the passivation for both tubes. Before my leaving I filled the Helium into the chambers by 1500 mbar for leakage checking. I will continue to passivate the tubes.

I installed all windows in the afternoon, and made the passivation for both tubes. Before my leaving I filled the Helium into the chambers by 1500 mbar for leakage checking. I will continue to passivate the tubes.

Tuesday, September 05, 2006

TWIN windows became dirty again

After the labor day, we tried to continue the experiments. So I filled the new gases into the TWIN excimer amplifier this morning. The output energy of the front end was 34.7 mJ, Alex already used this beam to align the target and x-ray spectrometer. Unfortunately, the energy was dropped to 7.7 mJ suddenly in the afternoon, I found there were small dust grains on the long chamber windows, which was similar to the status two weeks ago (on Aug. 22th). I cleaned the same windows on May 10th (http://xysong.blogspot.com/2006/05/twin-dirty-windows.html). It is very strange that the windows became dirty frequently. I guess the filter was dirty or something wrong inside the long tube.

Subscribe to:

Comments (Atom)